Research Resiliency Through Lean Labs

by David Sadat, and Canan Dagdeviren

Research Resiliency Through Lean Labs

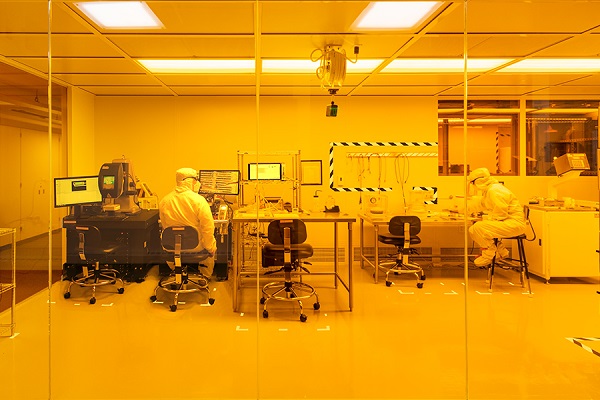

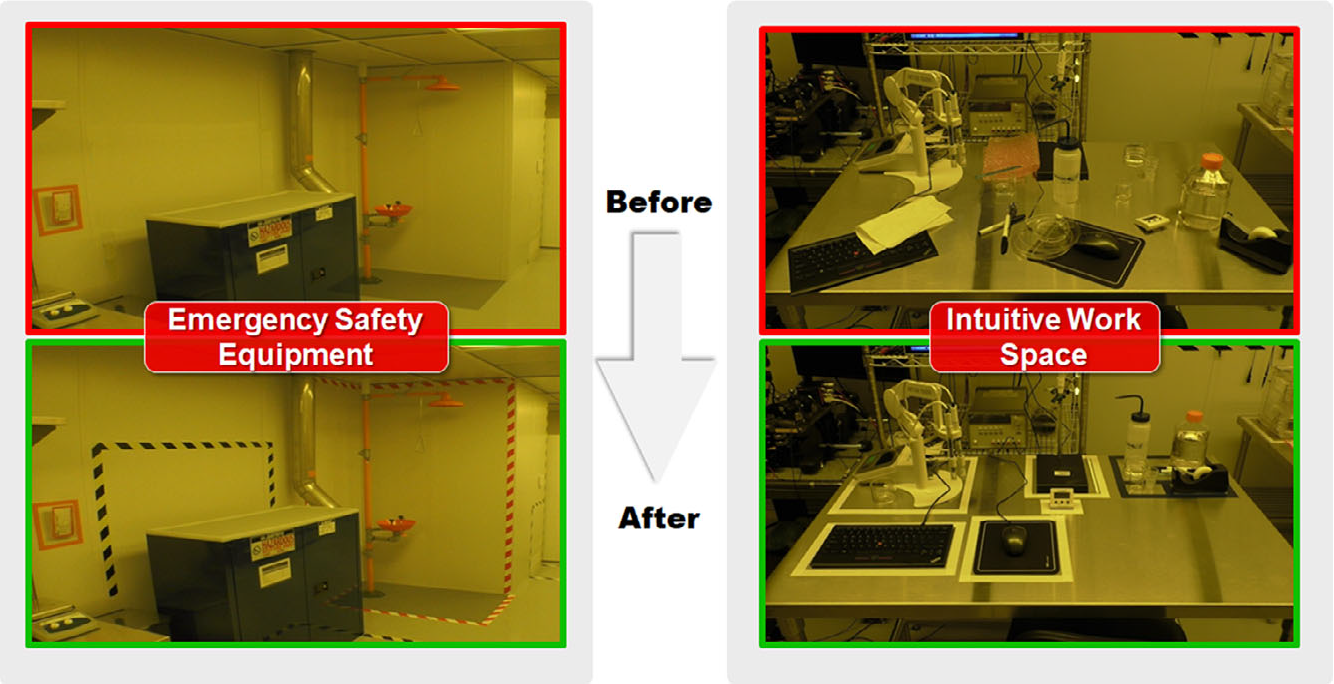

Academic research groups, especially the ones directed by new junior faculty, are under pressure to produce high-quality work timely while constrained by limited budget, resources, and lab space. A well-organized lab is crucial for a wide range of reasons, from keeping costs low, to protecting the health and safety of users. Our focus is on developing lab-level systems that create a lean and productive space in the context of academic cleanrooms. The efforts made at implementing the 5S organizational methodology to improve cleanroom functions, including regulatory compliance, organization, and resource stewardship are discussed. The quantifiable result is that chemical consumption spending is reduced by 41%, between 2018 and 2019, whereas materials consumption spending is reduced by 52%. Meanwhile, there is a 116% increase in the number of fabricated devices, showing greater output using less resources. This management system also proved itself to be beneficial during emergency situations. The recent COVID-19 pandemic is one such instance that showcased the ability to systematically ramp-down operations within 15 min, taking a huge burden away from the research group, and thus allowing us to focus on what is most important during this time of crisis: the health and safety of the group and community.

Related Publication

Research Resiliency Through Lean Labs

Contributors: David Sadat, Canan Dagdeviren