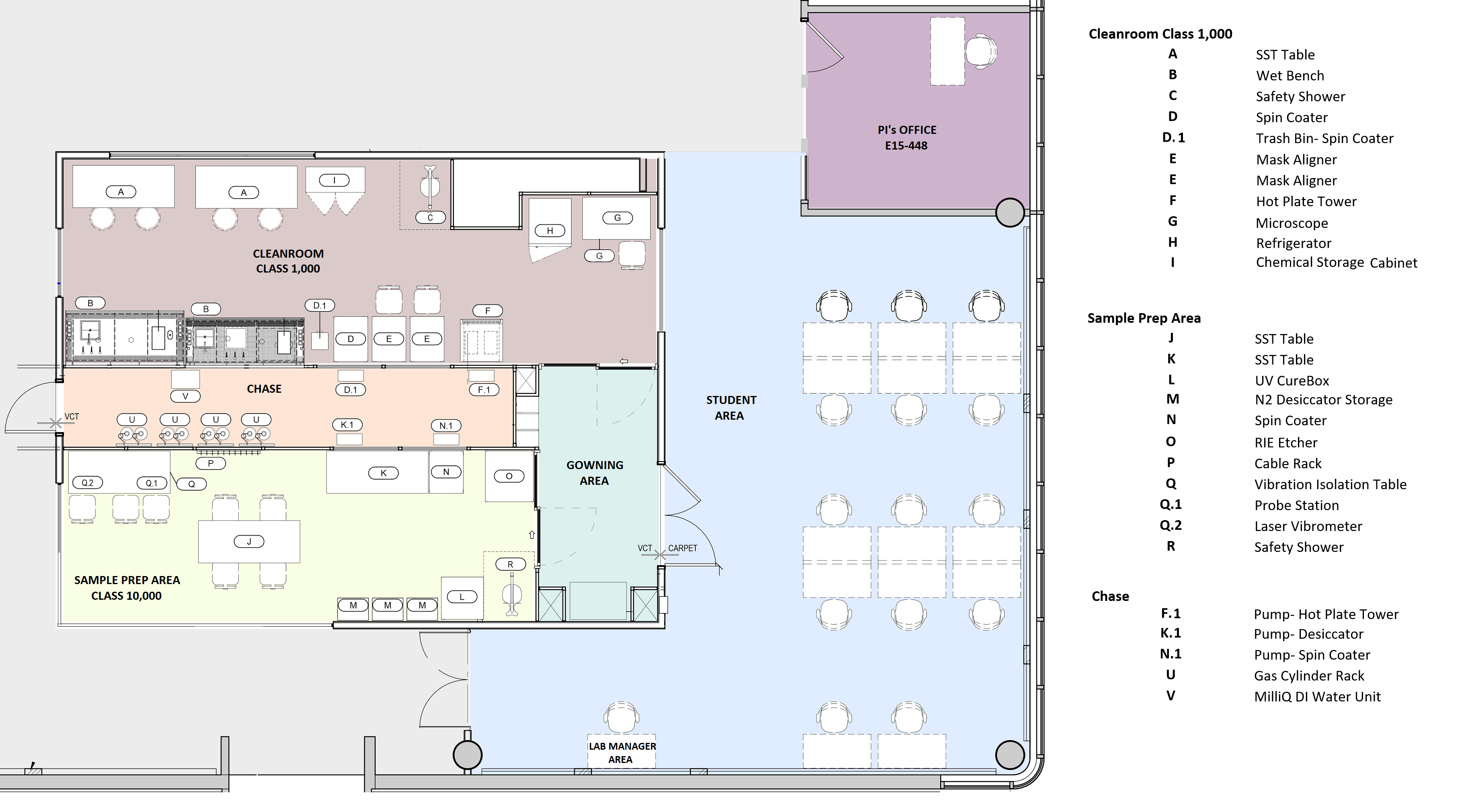

Cleanroom “YellowBox” Overview

Gowning Area

Cleanroom Area

Specimen Prep Area

Chase Area

The Conformable Decoders Group at the MIT Media Lab has a state-of-the-art cleanroom, called YellowBox, located in E15-443 at MIT in Cambridge, MA.

YellowBox is devoted to the exploration of novel materials, device design, and fabrication strategies to create micro- and nanoscale electromechanical systems with mechanically adaptive features, which allow intimate integration with the objects of interest. It is the first-of-its-kind cleanroom built inside the Media Lab (E15), which is currently the key facility to accomplish our research endeavors. YellowBox is physically transparent with glass walls, equipped with cameras to track researchers and processes in real time and has a special operation room (the chase) to manipulate and hack the traditional microfabrication tools for our evolving research needs.

YellowBox consists of three major components: a Gowning area, a Specimen Preparation Room of Class 10,000 of approximately 300 NASF and a Cleanroom of Class 1,000 of approximately 400 NASF. YellowBox is intended to accommodate a research group size of approximately 7 to 8 students/researchers. YellowBox supports the design and evaluation of novel devices with state-of-the-art microfabrication and characterization equipment, including: two wet benches (one for photolithography and the other for acids), two mask aligners, a vacuum oven, two spin coaters, a reactive ion etcher, sophisticated pH measurement instruments, a laser vibrometer, an optical microscope, several stainless steel preparation tables, a probe station with high-end characterization electronics and vented specimen and chemical storage cabinets.

The Conformable Decoders’ YellowBox is unique for creating unusual electromechanical and electrochemical systems such that the process flows and floor layout are optimized for the use of both traditional and non-traditional materials. Spin coating of (a) photoresist and (b) silicone-based material are executed on separate Headway spin coater units. The entire facility is kept under UV filtered light, allowing researchers to freely move between spaces to access specialized fabrication characterization equipment, without the risk of yield loss due to accidental photoresist exposure. YellowBox is supported by full-time staff including: a dedicated administrative assistant and a cleanroom laboratory manager with experience in microfabrication operations and development environments.

Gowning Area

The Gowning Room entry is granted via proximity Key Card access for authorized users. A Laboratory Information Management System (LIMS) is used to track user access to the cleanroom and for equipment reservations, including processing logs to record experiment data for later review. An iPad is seamlessly mounted near the YellowBox entrance, for users to immediately sign-in to gain access to YellowBox. The gowning room is kept clean to Class 10,000 standards by HEPA filters above. Inside the gowning area, a Terra Universal Garment Storage Cabinet (4101-05D) securely houses and separates the Class 1,000 garments from the Class 10,000 garments to prevent cross-contamination. A Terra Universal stainless steel bench nearby allows users to sit down while gowning-up, and a small stainless steel table allows users to conveniently wipe down items before bringing them into the cleanroom. A large mirror is conveniently mounted near the gowning bench, for users to ensure their garments are donned properly. Independent access to both Cleanroom spaces is provided to both (a) the Class 10,000 Specimen Preparation room and (b) the Class 1,000 Cleanroom microfabrication space by passing through sliding glass doors, which is activated by a proximity sensor. Access to the Class 10,000 Specimen Preparation room will be permitted with a lab coat, while access to the Class 1,000 Cleanroom requires complete gowning. The facility operates with the use of a laundry service, for washable cleanroom garments, with approximately three-week intervals.

Cleanroom Area

The Class 1,000 microfabrication cleanroom space is intended for device microfabrication, consists of many required tools and equipment for successfully building a miniature device. Below is the list of equipment offered in the Class 1,000 cleanroom:

- Air Control Polypropylene Wet Bench

The polypropylene wet bench is intended for use with photoresist developing. - Air Control Stainless Steel Wet Bench

The Air Control wet bench is used to etch devices in acids, including but not limited to: hydrofluoric acid (HF), hydrochloric acid (HCl), nitric acid (HNO3), buffered oxide etch (BOE), gold (Au) etchant and chromium (Cr) etchant. - Sample Preparation Tables

There are two large tables of 25sqft size, for use during device preparation activities. - Headway Spin Coater

The Headway Spin Coater PWM32-PS-R790 in the Class 1,000 Cleanroom space is used to spin coat substrates of various sizes with photoresist. - Karl SUSS Mask Aligner- MJB3

The Karl SUSS MJB3 mask aligner is located immediately near to the Headway Spin Coater, and is used for alignment of the photoresist-coated substrate to the photo-mask, and the controlled UV exposure of the photoresist film, in addition to be used as pick-and-place tool during transfer-printing process. - Karl SUSS Mask Aligner- MJB4

The Karl SUSS MJB4 Mask Aligner, also near to the Headway Spin Coater, is used for alignment of the photoresist-coated substrate to the photo-mask, and the controlled UV exposure of the photoresist film. - Hot Plate Tower

A stainless steel tower houses multiple hot plates, with the hot plates being housed inside the tower to exhaust the surrounding air and prevent particles from settling onto the devices during baking. - High Temperature Vacuum Oven

The VWR vacuum oven is a 12.5 L unit that operates under vacuum and vents to a facilities exhaust. - BX61 Olympus Microscope

The Olympus optical microscope is conveniently located near the mask aligner, and includes many features including: polarization, a Moticam image capture system, and advanced image analysis software to view the contrast between thin film device layers. - Flammable Material Storage Refrigerator

The 850 L Flammable Material Storage Refrigerator houses photoresist chemicals for long-term storage.

Specimen Prep Area

The Specimen Preparation room is isolated from the Class 1,000 microfabrication cleanroom, and serves the purpose of device characterization. This space is outfitted with the following equipment:

- Probe Station

The Cascade Microtech EPS150P Probe Station is an easy to use and highly precise manual probe platform for wafers and substrates up to 150 mm, with a vibration-isolation table to protect quality over the measurement duration. - Stanford SR 810 Lock-in Amplifier

The Stanford SR 810 Lock-in Amplifier is used to detect and measure very small AC signals. - Textronix TDS2024C Oscilloscope

The Textronix TD2024C is a compact tool for digital real-time sampling of electronic signals. - Keithly 3390 Function Generator

The arbitrary waveform generator provides both a full set of standard waveforms and custom waveform generation. - Keysight E4980A Precision LCR Meter

The E4980A precision LCR meter provides the best combination of accuracy, speed, and versatility for a wide range of component measurements. - Keithley 4200A-SCS

The Keithley 4200A-SCS delivers synchronizing current-voltage (I-V), capacitance-voltage (C-V) and ultra-fast pulsed I-V measurements. - Polytec MSA 500 Laser Vibrometer

The Polytec MSA-500-TPM is a sophisticated measurement tool for the analysis and visualization of structural vibrations and surface topography in micro structures and devices. - Advanced Vacuum VISION 320 Reactive Ion Etcher

The Advanced Vacuum VISION 320 Reactive Ion Etcher provides etching capabilities over a variety of materials and substrates for non-caustic etching. It can also be easily expanded to etch various materials, by adding new gas lines. - Mettler Toledo S220 SevenCompact Benchtop pH Meter

The Mettler Toledo S220 pH Meter is used to continuously measure pH and to record the data digitally. - Sample Preparation Tables

There are two large tables of 20sqft size, for use during device preparation activities. - SZ B Plastic Vacuum Desiccator

The vacuum desiccator is used to outgas and evacuate a beaker containing a substrate/sample filled with epoxy-resin or silicone based polymers. - Overhead Retractable Power Cable Receptacle

Retractable power receptacles are mounted on the ceiling and are located above the sample preparation tables. - Terra 3949-29B N2 Desiccator for Sample Storage

The nitrogen-purged clear acrylic cabinet-style desiccators are used to store sensitive items.

Chase Area

The chase for YellowBox is essentially the heart and operation center for the YellowBox. All adjustable gauges, controls, valves, and switches are accessed in the service chase by authorized personnel only, and is kept isolated from the users/researchers. The walls are lined with windows to give a complete view of the Class 1,000 and Class 10,000 spaces without the need to gown-up and enter the cleanroom environment.

Gases are supplied to the cleanroom via compressed gas cylinders with Linde 7900 Changeover System for automatically switching out of empty gas cylinders to prevent interruptions to cleanroom operations. Gases used currently include ultra-high purity Argon, Nitrogen, Oxygen, and CF4. More gases can be added or removed as the needs of the Conformable Decoders research group changes.

The facilities supplied from the chase to the wet benches include: process vacuum, nitrogen, compressed dry air and deionized water. A Milli-Q unit supplies deionized water (Type 1, ~18MOhms). The wet bench hoods are exhausted for low concentration, corrosive fumes generated by pouring small quantities of acids and developers.